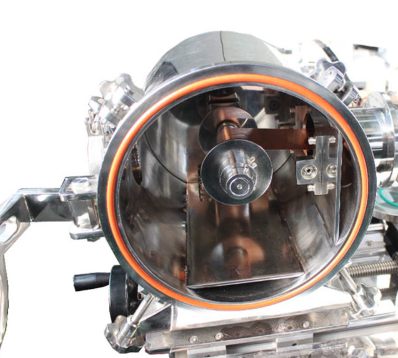

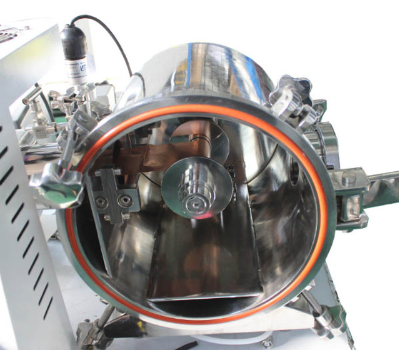

model:PT-T1200RTR-III-80-PE

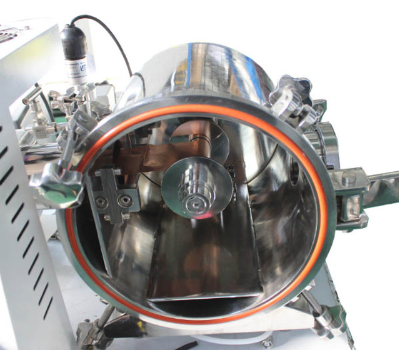

Plasma Enhanced Roll to Roll Chemical Vapor Deposition System for graphene production

Application: It is mainly used for continuous growth of graphene films or continuous special equipment for linear materials.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

IntroductionJzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The system consists of heating furnace,3 channels MFC,vacuum unit,RF generator,cooling device,Sealing device for collecting and releasing copper foil and automatic control system.The unwinding roller and the winding roller are respectively installed in the sealing device for collecting and releasing copper foil, and a cooling device is installed between the output material exhaust cavity and the furnace body. JzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

JzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1.Heating furnaceJzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Max. Temp |

1200℃ |

|

working temp |

≤1100℃ |

|

tube zie |

Φ80mm |

|

insulation material |

Alumina, high temperature fiber products |

|

thermocouple |

K type |

|

Temperature Accuracy |

±1℃ |

|

Temp. control |

· PID automatic control and auto-tune function.JzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· 30 programmable segments for precise thermal processing.JzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

· Built-in protection for the over-heated and broken thermocouple. |

|

Heating Zone Length |

200+200+200mm |

|

Heating Element |

Fe-Cr-Alloy adopted by Mo |

|

power |

single phase,220V,50Hz |

JzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2、PE systemJzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Power output range |

0W~500W |

|

Maximum reflected power |

100W |

|

RF output interface |

50 Ω, N-type, female |

|

Power stability |

≤5W |

|

Harmonic component |

≤-50dbc |

|

Supply voltage |

Single-phase AC (187V-253V) Frequency 50/60HZ |

|

Overall efficiency |

>=70% |

|

Power Factor |

>=90% |

|

cooling method |

Forced air cooling |

JzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3、Three-way proton flow control systemJzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

Connector type |

Double ferrule stainless steel joint |

|

Standard range (N2) |

200sccm,500sccm、1000sccmJzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

(Can be customized according to user requirements) |

|

Accuracy |

±1.5%F.S |

|

Linear |

±1%F.S |

|

Repeat accuracy |

±0.2%F.S |

|

Response time |

Gas characteristics: 1~4 Sec, electrical characteristics: 10 Sec |

|

Working pressure range |

0.1~0.5 MPa |

|

greatest pressure |

3MPa |

|

interface |

Φ6,1/4'' |

|

display |

4-digit display |

|

Working temperature |

5~45 high purity gas |

|

Pressure vacuum gauge |

-0.1~0.15 MPa, 0.01 MPa/div |

|

Shut-off valve |

Φ6 |

|

Internal and external double throwing stainless steel pipe |

Φ6 |

JzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4、Low vacuum unitJzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

relative humidity |

≤85% |

|

working environment |

5℃~40℃ |

|

Working voltage |

220V±10% 50~60HZ |

|

power |

1KW |

|

Pumping rate |

10m³/h |

|

Ultimate vacuum |

5X10-1Pa |

|

Working pressure range |

1.01325X105~1.33X10-2Pa |

|

Withstand voltage |

0.03MPa |

|

Oil capacity |

1.1L |

|

Inlet port diameter |

KF25 |

|

Exhaust port diameter |

KF25 |

|

noise |

50dB |

|

Connection method |

Using bellows, the manual flapper valve is connected to the bellows |

JzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

JzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

JzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

JzpMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac