0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

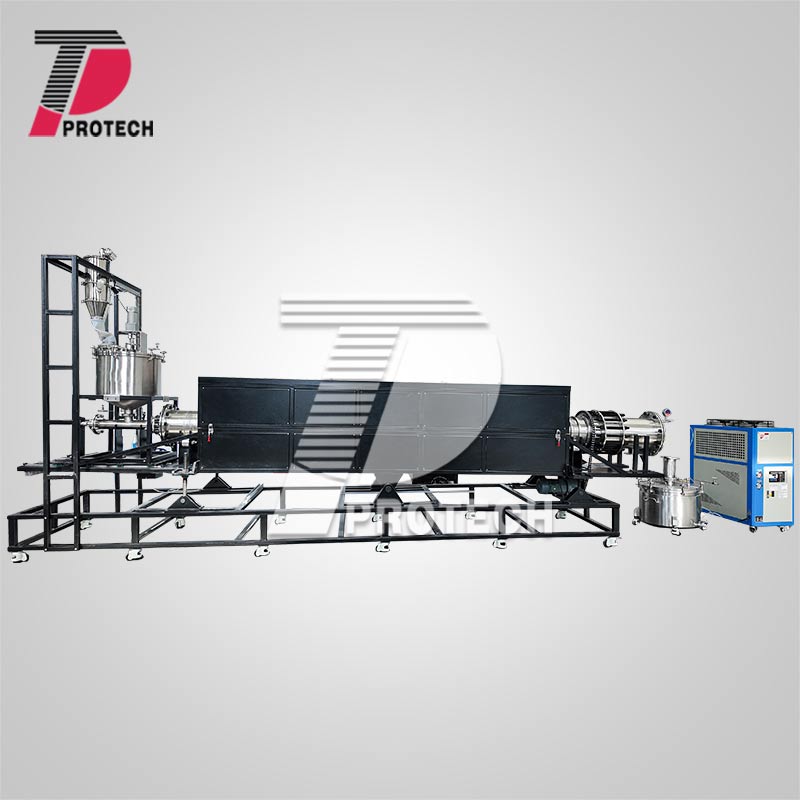

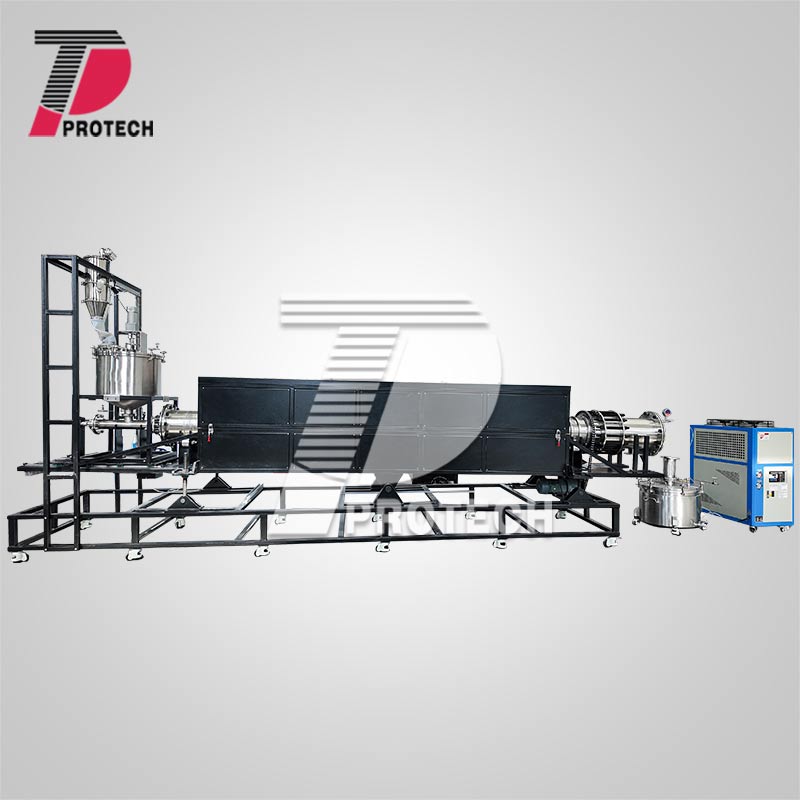

| Model | PT-TX1000-H325CK3W |

| Part I Furnace body | |

| Furnace structure | Carbon steel outside shell Double-layer structure with cooling fan |

| Furnace door | Electric opening |

| Max. Temperature | 1100℃ |

| Continuous working Temperature | ≤1000℃ |

| Heating Rate | 0-20℃/min, Suggestion 0~10℃/min |

| Number of heating zone | Three |

| Heating zone length | 660mm*3, Total heating zone length 1980mm |

| Tube size | OD325/ID305 x L3200mm (Can be customized according to customer needs) |

| Material of tube | 310S stainless steel Inside welding lifting blades, 180 degrees apart |

| Heating Element | SiC rods |

| Temperature Control Accuracy | ±1℃ |

| Tube rotating Speed | 1.5- 3RPM variable |

| Furnace Tilt Angle | 3° |

| Thermocouple | N type 3 pieces of temperature control thermocouples + 1 piece of monitor thermocouples |

| Chamber material | Alumina polycrystalline Fiber |

| Sealing | Graphite compact seal |

| Feed structure |

310S stainless steel screw feeder; Screw feeder tube size: OD133xL1000mm; (Can be customized according to customer needs) |

| Collect structure |

Size: ID500xH520mm With Removable sealing flange lid, one gas inlet on the lid. (Can be customized according to customer needs) |

| Rotary structure | Chain |

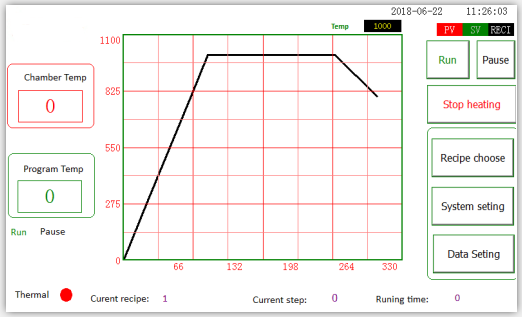

| Part II Controller system | |

| Temperature Controller |  Can output temperature readings to laptop in real time; Can output temperature readings to laptop in real time;Independent controller cabinet; 10 inch touch screen; 3 temperature controllers witch can control each zone separately; PID automatic control via SCR power control; 30 steps programmable; Over temperature protection and alarm. |