model:PT-V1600-36LW

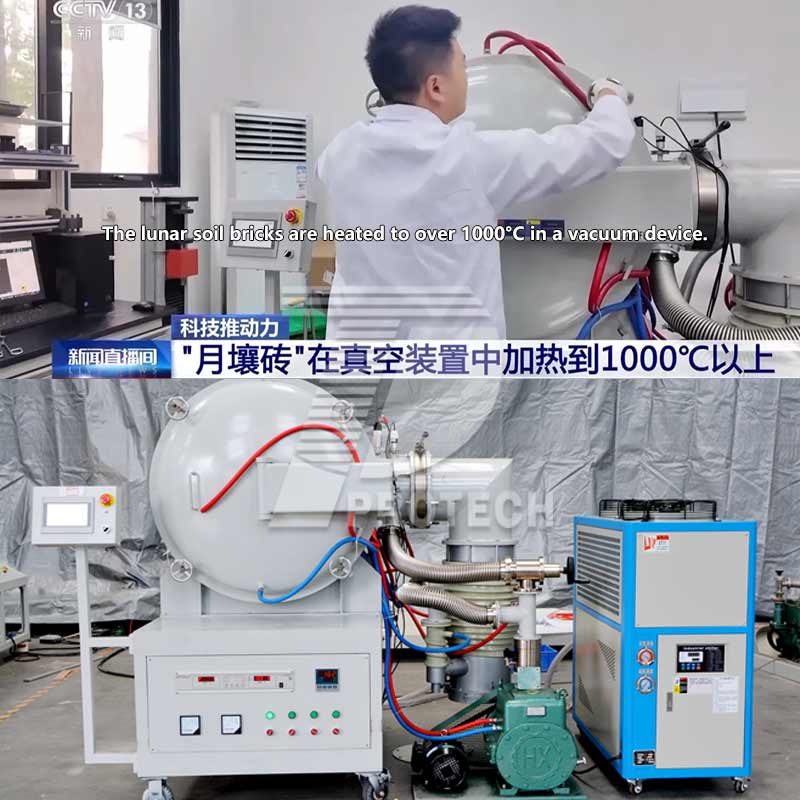

PT-V1600-36LW vacuum furnace for lunar soil brick sintering

Application: The PT-V1600-36LW vacuum heat treatment furnace is suitable for high-temperature hot forming of new materials such as powder metallurgy, functional ceramics, silicon carbide, and alumina. It is mainly suitable for bright annealing of high-speed steel, mold steel, tool steel, alloy steel, titanium alloy and other materials after quenching.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Introduction:gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The PT-V1600-36LW vacuum heat treatment furnace is mainly composed of a vacuum furnace body, a heating furnace, a temperature measurement system, a vacuum system, a control system, a water cooling system, etc. The PT-V1600-36LW vacuum heat treatment furnace is a complete set of equipment for high-temperature heat treatment under vacuum (or other atmosphere) conditions. It mainly uses alumina fiber as the furnace material, silicon molybdenum rods as heating elements, double-layer water-cooled vacuum chamber, and can be equipped with a circulating water refrigeration system to cool the furnace body.gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Application:gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The equipment combines vacuum/atmosphere and high-temperature heating together, and is suitable for high-temperature hot forming of new materials such as powder metallurgy, functional ceramics, silicon carbide, and alumina. It is mainly suitable for bright annealing of high-speed steel, mold steel, tool steel, alloy steel, titanium alloy and other materials after quenching. Eliminate residual internal stress of forgings, welded parts, cold stamping parts, and workpieces after quenching to prevent deformation and cracking of workpieces.gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Features:gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

1.The double-layer furnace body structure is made of high-quality carbon steel, with a vacuum exhaust interface and a charging and discharging valve on the outside, and excellent sealing.gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2.The equipment can achieve the best temperature uniformity and heating uniformity of the workpiece.gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3.It can achieve high vacuum and ensure the quality of workpiece processing.gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4.It consists of a touch screen, a programmable controller, a temperature control meter, etc. to realize power supply, control, recording, monitoring, and alarm protection functions.gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

5.The temperature control adopts an intelligent temperature controller with a temperature control accuracy of ±1℃. The furnace temperature can be digitally displayed on the control cabinet, which is convenient for operators to observe and record.gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

6.It is equipped with a water pressure alarm system to protect when the water is cut off so that the backup water system can be turned on.gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Protech vacuum furnace equipment helps China's aerospace industry development--Sintering of lunar soil bricks.gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

| Model |

PT-V1600-36LW |

| Shell structure |

double shell |

| Heating element |

high temperature silicon molybdenum rod |

| Furnace material |

alumina polycrystalline fiber |

| Chamber size |

400×300x300mm (length×width×height) (can be customized according to your needs) |

| Maximum temperature |

1600℃ |

| Working temperature |

≤1500℃ |

| Constant temperature accuracy |

±1℃ |

| Temperature measuring element |

B-type thermocouple |

| Temperature control protection |

With over-temperature and broken couple protection function |

| Protective atmosphere |

Argon or high-purity nitrogen and other inert gases |

| Gas flow |

The furnace body has a reserved air inlet, which can flow any inert gas |

| Vacuum unit |

Mechanical pump + diffusion pump |

| Ultimate vacuum degree |

6.7*10-3Pa (empty furnace, cold state, purified) |

| Vacuum control |

Manual opening and closing of high vacuum valve |

| Vacuum gauge |

Composite digital display vacuum gauge |

| Water cooler |

Circulating water cooler, cooling furnace door and vacuum pump unit (optional) |

gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacgK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacMore equipment details photos:

gK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacgK2Muffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac