0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

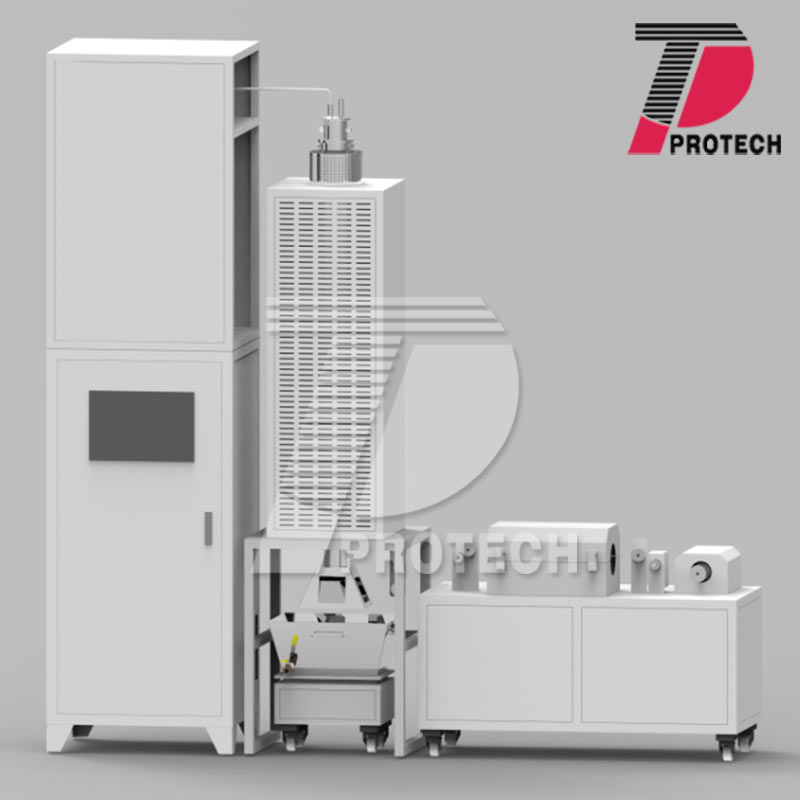

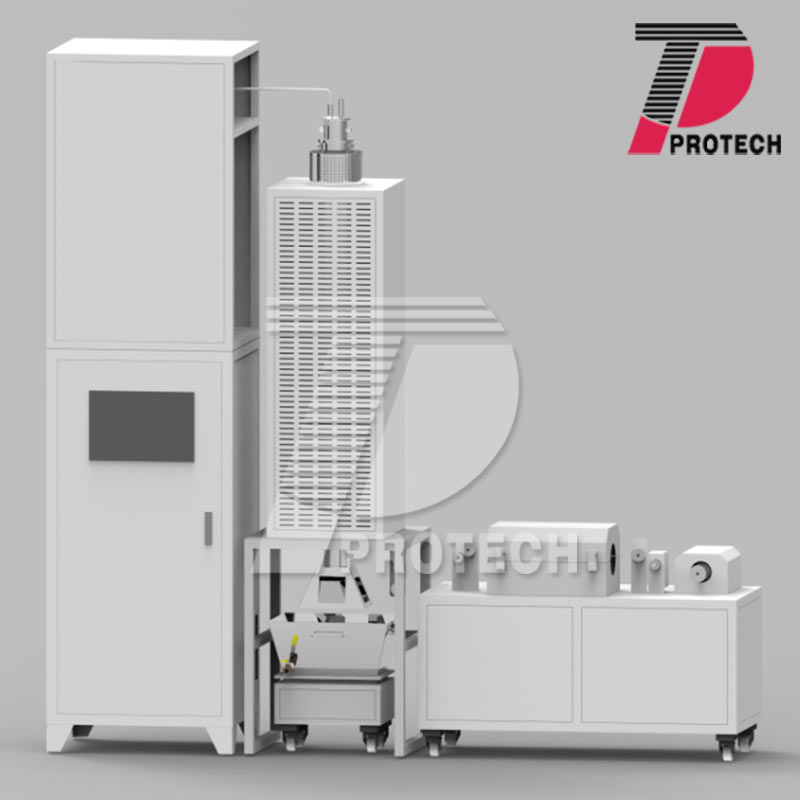

| Furnace structure | Double-layer shell structure with air cooling system, the shell surface temperature is less than 60℃ |

| High-purity alumina is used as the furnace material, and the surface of the furnace is coated with a 1750 ℃ alumina coating imported from the United States, which can improve the heating efficiency (20%) and prolong the service time of the instrument |

|

| Furnace tube material | 99.8% high purity corundum tube |

| Furnace tube size | OD: 80mm x ID: 72mm X Length 1500mm (Can be customized according to customer needs) |

| Stainless Steel Vacuum Flange | A set of stainless steel vacuum flanges are included in the instrument (with stainless steel needle valves and mechanical pressure gauges installed) |

| Armored flange can be used to extend the thermocouple to the inlet to measure its temperature | |

| Flange interface | In order to obtain better vacuum degree faster, KF25 adapter can be used |

| In order to better pass the gas, you can choose 1/4" stainless steel ferrule fittings | |

| Flange interface can be customized | |

| Heating element | High quality silicon carbide rod |

| Operating temperature | Continuous working temperature: ≤1300℃ |

| Maximum operating temperature: 1400℃ | |

| Temperature Control System | Adopt PID method to adjust temperature, and can set 30 steps of heating and cooling program |

| Use S-type thermocouple for temperature measurement and temperature control | |

| Temperature control accuracy | ±-1 ℃ |

| Heating zone length | 700mm+400mm (Can be customized according to customer needs) |

| Length of constant temperature zone | 800mm (Can be customized according to customer needs) |

| One year warranty (excluding furnace tube, heating element and seal wear parts) | |