0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

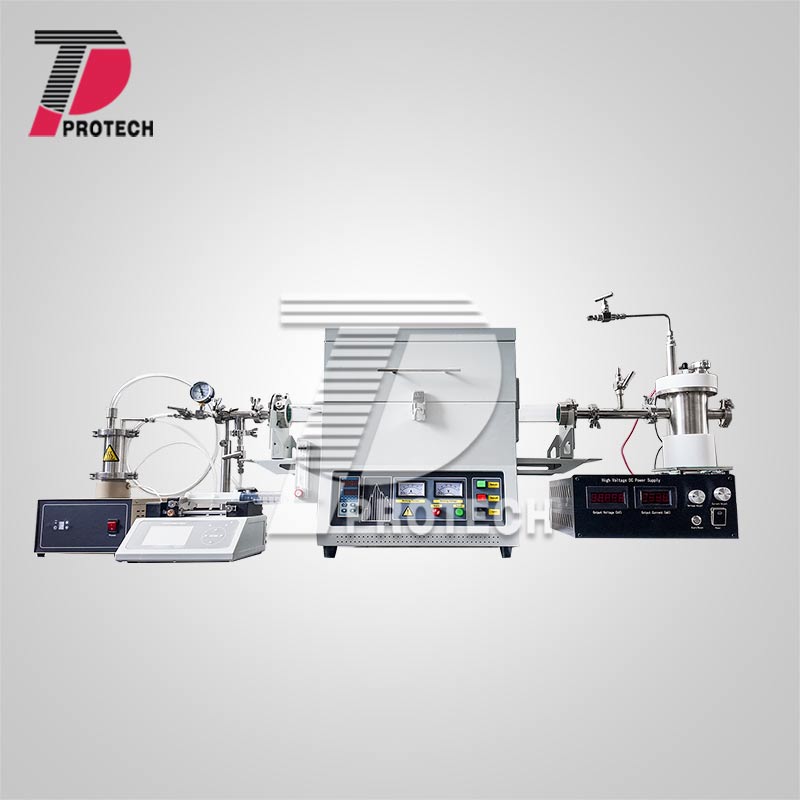

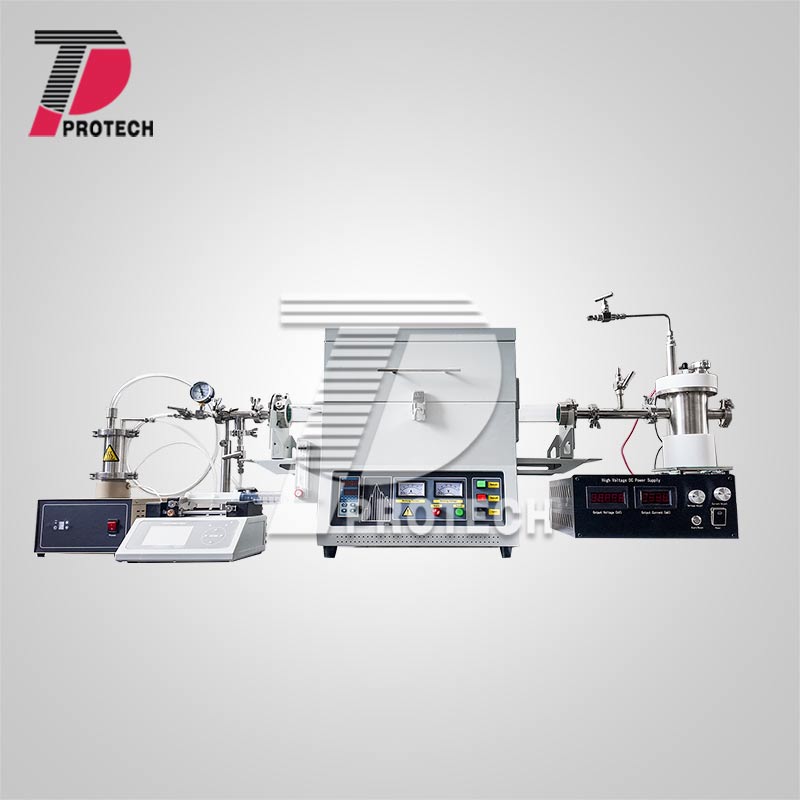

| Model: PT-TG1100S50LK1W | |

| Part I Aerosol generator | |

Atomization device: |

Equipped with a 1.7MHz ultrasonic atomizer, the liquid can be atomized into liquid particles and introduced into a tube furnace. 20VAC, 1.7MHz ultrasonic atomizer • The liquid tank comes standard with 316 stainless steel,and sealed with a fluorine rubber seal; • Atomization amount can be set from 1 to 8, and the amount of atomization can be controlled by adjusting the size of the gear; • It can realize two functions of continuous operation atomization and regular operation atomization. The timing can be adjusted from 30 minutes to 180 minutes (adjust the gear every 30 minutes). |

| Liquid injection system | • A standard set of liquid injection pumps for automatic liquid feeding • The syringe pump is equipped with a plastic syringe with a maximum volume of 60ml for holding liquids; • Syringe pump speed adjustment range: 0.004ml / min—70ml / min |

| Part II Tube Furnace | |

| Structure | Heating section (tube furnace): The maximum temperature of the tube furnace can reach 1200 ° C. |

| Contious Working temperature | ≤1100℃ |

| Recommended heating rate | ≤10℃/min |

| Heating Elements | Fe-Cr-Al Alloy doped by Mo |

| Hot Zone | 300mm |

| Temperature control system | -Digital temperature controller with 30 segments should be programmable for precise control of heating rate, cooling rate and dwell time. -The built-in overtemperature alarm and protection must allow operation at a temperature sensitivity of +/- 1 ºC. |

| Furnace Tube | Using high-purity quartz tube. Quartz tube size: ID44mm*OD50mm . About 1200mm length . Can be customized according to customer needs |

| Sealing Flange | The left end is equipped with Water-cooled flange with needle valve and mechanical pressure gauge. The right end is equipped with KF25 interface is directly coupled to the electrostatic precipitator. |

| Flow Meter | A 0-100 ml/min floating flow meter is included to control the carrier gas flow rate. |

| Part III Electrostatic precipitation (precipitation) | |

| High voltage power supply | • Digital display voltage and current value. • Output voltage and current can be set on the front panel and read from the digital display. Constant current/Constant Voltage mode of operation. Built-in Arc protection circuit.  |

Nano powder collector |

•Up to 30 kV and 1 mA. The use of KF25 enables the quick coupling to the furnace processing tube. Adjustable supports keep the collector leveled with the furnace tube. |