0-2000°C RESEARCH MATERIAL & HEATING TREATMENT'S LEADER

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

The daily working temperature of the PT-TX1000-H150LK1 1000 ℃ vacuum powder treatment rotary tube furnace is 1000 degrees. The furnace is lined with alumina fiber, with intelligent temperature control, simple operation, and high intelligence. Mainly used in fields such as crystal annealing, electronic lighting, two-dimensional material sintering, atmosphere protected sintering, vacuum coating, CVD experiments, and material composition determination. It belongs to a type of inclined rotary tube furnace.

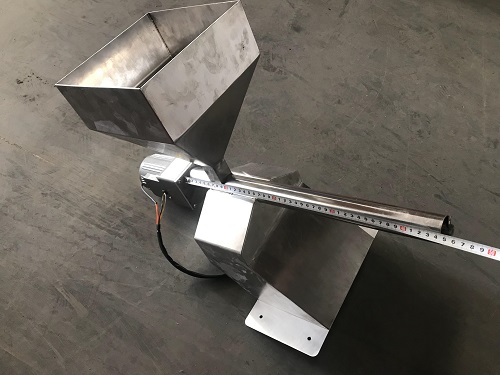

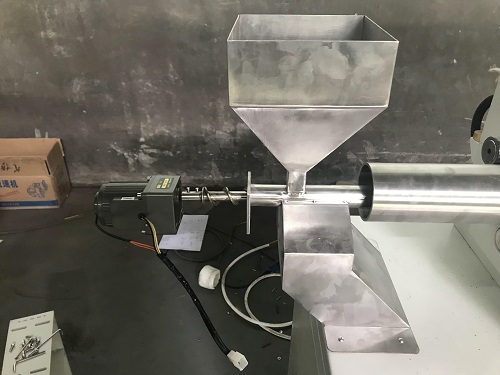

Actual photo of 1000 ℃ vacuum powder treatment rotary tube furnace

| Model | PT-TX1000-H150LK1 |

| Structure | Carbon steel outside shell Alumina fiber lining Double-layer structure with cooling fan Split type (Mechanical lifting upper cover.) |

| Tube | Stainless steel tube OD150* L1600mm Rate-adjustable rotation function 0-20r/m Clockwise and anticlockwise (Can be customized according to customer needs) |

| Sealing | Air-tight From funnel to collection tank. Analog pressure gauge with measurement range from -0.1Mpa to 0.15Mpa KF40 Gas-in port and gas-out port. |

| Funnel | 5L volume (Can be customized according to customer needs) |

| Pusher | Mechanical type  Adjustable pushing rate |

| Collection tank 5L |  |

| Heating zone length | 600mm (Can be customized according to customer needs) |

| Working Temperature | ≤1000℃ |

| Temperature detector | N-type thermocouple |

| Temperature Control | PID automatic control via SCR (Silicon controlled rectifier) Power control with phase angle fired, current limiting resistor 30 programmable segments for precise control Bulit-in PID auto-tuned function with overheating & broken thermocouple broken protection. Over temperature protection and alarm allows for operation without attendant |

| Heating Rate | Suggestion: ≤10℃/min |

| Temperature Accuracy | +/-1℃ |

| Heating Element | SiC |

| Tilting angle | 0-15 |

| Production Period | 25 working days |

| Warranty Period | 1 year (Lifetime support) |

Actual photo of 1000 ℃ vacuum powder treatment rotary tube furnace