model:PT-1200T

Automatic pressure control CVD tube furnace

Application: Suitable for CVD process, such as silicon carbide coating, ceramic substrate conductivity test, controlled growth of ZnO nanostructures, ceramic capacitor (MLCC) atmosphere sintering and other experiments.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Brief Introduction: GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacIt’s mainly used for the preparation of rare earth, electronic lighting, crystal annealing, bio ceramics, electronic ceramics, special alloys, magnetic materials, precision casting, metal heat treatment and other industrial vacuum sintering, protective atmosphere sintering, vacuum deposition, CVD experiments, material composition measurement occasions.GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere FurnacMain features:GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac1. Great temperature uniformity.GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2. Over temperature protection and alarmGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3. PID automatic control via SCR power control

Part I

Technical Parameter:

| Model |

PT-1200T |

| Display |

LED |

| Max. Temp. |

1200C |

| Working Temp. |

≤1100℃ |

| Heating Rate |

Suggestion 0~10℃/min(max. 20℃/min) |

| Temperature Zone |

200mm+200mm+200mm |

| Temperature Control Accuracy |

±1℃ |

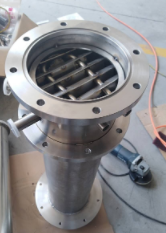

| Tube Size |

Φ50mm x 1200mm OD x L |

| Heating Element |

Fe-Cr-Al Alloy doped by Mo |

| Thermocouple |

K Type |

| Max. Power |

6.0 KW |

| Working Voltage |

AC 208V-240V single phase, 50 Hz (or according to your requirement) |

| Temperature Control |

PID automatic control via SCR power control |

| Heating curves |

30 steps programmable |

| Chamber material |

Alumina Fiber |

| Warranty |

One year limited warranty (Consumable parts such as heating elements are not covered by the warranty) |

| Standard Accessories |

Hook x 1 pieceGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Tube block x 1 pairGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Silicone O rings x 4pcs |

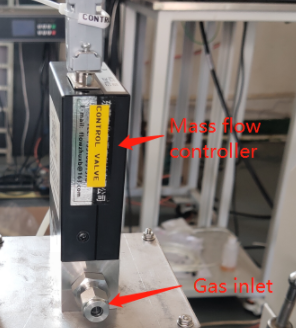

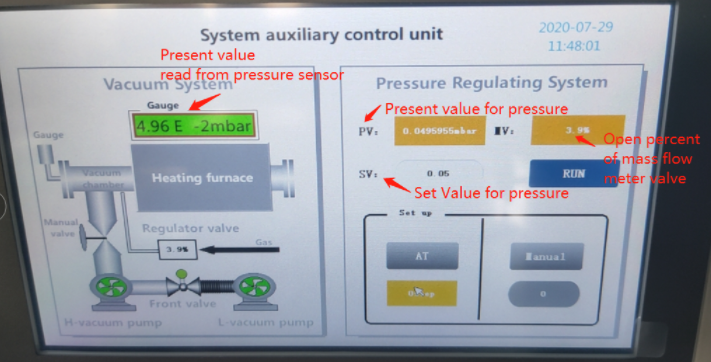

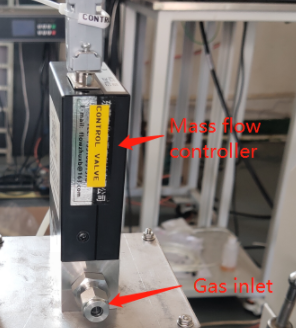

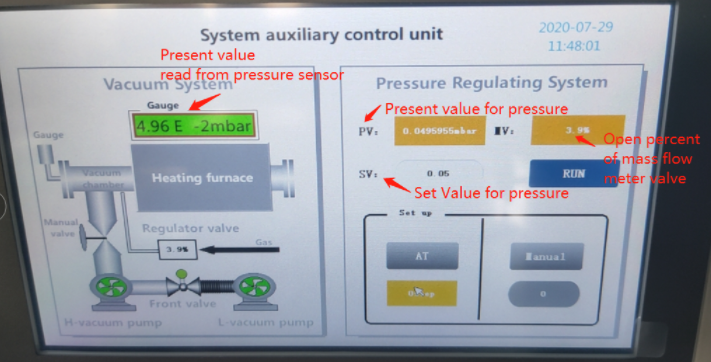

Pressure Regulation System

| One mass flow meter |

Which can regulate according to pumpGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

pressureGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

pressure sensorGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

(inficon brand: measuring range:3.8x10-5 to 1125GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Torr ) installed on outlet of furnace tube.GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

| Touch Screen PLC Controller |

Regulate pressure from 50-300torrGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

| Notice: |

The regulate pressure is under furnace in horizontal direction.GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The result maybe different in vertical direction. |

|

Installed on gas inlet side of furnaceGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

tubeGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Measuring range: 1×105~1×10-1Pa |

| Display |

LCD Touch Screen |

| Working Temperature |

5~45 ºC |

| Max. Pressure: |

3x106 Pa |

| Accuracy: |

±1.5% FS |

| Liner |

±(0.5-1.5)%F.S. |

| Duplicate accuracy: |

±0.2%F.S. |

| Structure |

Four precision mass flow meters:GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

MFC 1: Flow range from 0~600 sccm for ArGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

MFC 2: Flow range from 0~600 sccm for N2GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

MFC3: Flow rang from 0~600 sccm for forming gas (5%H2+95%N2) GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

MFC4: Oxygen:0-600sccmGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

One gas mixing tank is installed on bottom caseGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

5 stainless steel needle valves is installed on left side of bottom case to control 4 type gases mixing manually. |

| Pls note |

Liquid or corrosion not supported. |

GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Part VGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Scroll Vacuum PumpGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Item Introduction:GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Scroll pump is a new kind of oil-free mechanical pump with features of simple construction,GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

good sealing, high vacuum ect. As a high technology product, it has highly technical requirement in desigh and manufacture. With benefits of low consumption, long working life, high reliability, and low noise, It has incomparable advantages in the application of clean process and has been popularly used in the market. GVD, GSP series scroll dry pumps are scroll dry pumps with excellent performance and obvious price competitiveness, which are introduced by Baosi Vacuum for the characteristics of downstream applications at home and abroad.GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Application:GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Clean vacuum, Backing turbomolecular pumps, Library, Analysis equipment, Leak detection, Beam line, Scientific researching, Medical equipment, Distillation/extraction/filtration, Laser, Semiconductor(LED/LCD), Photovoltaic, Coating(PVD/CVD), Battery, Glove box, Beam welding/laser welding, Space simulation.GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Technical Parameter

| Nominal Rotation Speed |

1800 rpm |

| Displacement |

3L/S |

| Ultimate Vacuum |

0.008mbar |

| Motor Power |

400W |

| Voltage Input |

Single Phase 100-240V |

| Dimensions |

430×255×290mm (L×W×H) |

| Noise Level |

54dBA |

| Inlet Flange |

NW 25 |

| Exhaust Flange |

NW 25 |

| Max Water Vapour Pumping Rate |

100 gh-1 |

| Leak Tightness |

< 1×10-6mbar·l/s |

| Weight |

28kg |

| Cooling System |

Air cooled |

| Operating Temperature |

10 to 40℃ |

| The cart, bellow and clamp are included for one pump. |

|

| Cold Trap |

Customized model,need to cooperate with water chillerGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Part VII Water ChillerGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

| Model |

CW-5000 |

| Power Supply |

220V 50Hz |

| Cooling Capacity |

1000W |

| Refrigerant Type |

R134a |

| Precision |

± 0.3℃ |

| Pump Power |

0.03 kW |

| Max. Lift |

8M |

| Flow |

10L/min |

| Tank Capacity |

7L |

| Inlet and Outlet |

Internal Φ8mm speedy connectorGloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Pagoda-shape connectors |

| Weight |

28 Kg |

| Control Type |

Digital Display |

| Dimension |

55*28*43cm (L*W*H) |

GloMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

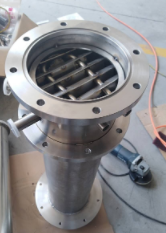

Part VIII Filter

| Used in the inlet of vacuum pump |

|