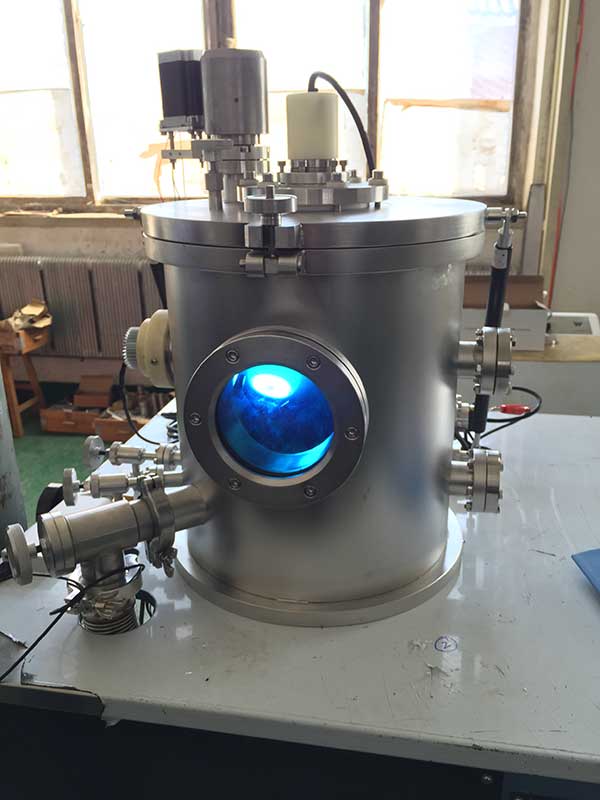

model:300x350mm

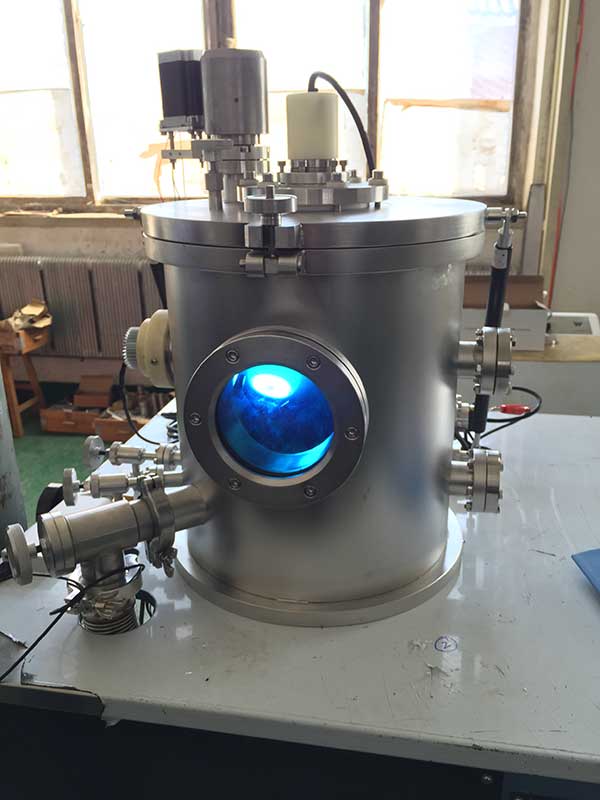

Dual Target High-vacuum Magnetron Coating Sputtering System

Application: Mainly used to prepare metal, semiconductor, and insulator materials. And it has the advantages of simple equipment, easy control, large shell and strong strength.

Contact us for customize

send-email:

info@lab-furnace.com

Detailed Parameters Of The Product

Bried Introduction:iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

This equipment is a small dual-target magnetron sputtering coating equipment. After modular design, the system is easy to install, flexible, and easy to maintain, suitable for scientific research and teaching experiments. It consists of a single-chamber ultra-high-vacuum dual-target magnetron sputtering chamber, which consists of a sputtering vacuum chamber and a pipeline. Equipped with a side-pumping system, the sample can be replaced without stopping immediately after startup, and the repeatability is good. It is used for plating various single-layer films and multi-layer film systems, and can realize single-target independent, dual-target rotation, dual-target co-sputtering and other sputtering modes. At the same time, reactive magnetron sputtering can be realized to prepare nitrides, oxides, etc., and can be plated and magnetically permeable metals, alloys, compounds, semiconductors, dielectric composite films and other chemical reaction films. As the test equipment, it has reached the best performance-price ratio.iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Main components and Technical Parameters:iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The system consists of a vacuum chamber, a rotating sample holder, a magnetron sputtering target, an armored heater, vacuum system, a vacuum measurement, a working gas path, and an electronic control system.iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The ultimate vacuum is better than: 9.0x10-5Pa (after baking and degassing)iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Vacuum leak rate is less than 2.0x10-8Pa.l / SiRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

After the system has been exposed to the atmosphere for a short time and filled with dry nitrogen, it will start pumping, which can reach 6.0x10-4Pa in 40 minutes;iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Vacuum after 12 hours of pump shutdown: ≤5 PaiRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

-

Vacuum Chamber:1 set

The vacuum chamber size is Ф300x350mm. It has a manual upper cover to assist the hydraulic structure. There is an observation window in the front. The sample table can be rotated to connect the flange interface of various specifications such as armored heaters, vacuum gauges, and vent valves. Made of materials, argon arc welding, the surface is electrolytically polished. Sealed with metal or fluoro rubber. Equipped with a standard electrical box in one cabinet.iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

-

Magnetron sputtering target assembly: 2 sets

2.1 Target size: Φ50mm (one of which can be sputtered magnetic material)iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2.2 One permanent magnet target and one strong magnetic target: RF sputtering is compatible with DC sputtering, and the target is water-cooled; with a manual baffle.iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

2.3 The two targets can be sputtered towards the center of the sample below, and the distance between the target and the sample can be adjusted from 90 to 110 mm.iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3. Vacuum Accessory PartsiRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3.1 Intake angle valve: 2 sets;iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3.2 RF100 observation window: 1 set;iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3.3 Observation window flange: RF100 x 2iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3.5 Resistance gauge: KF16 x 1iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

3.6 electrode lead: CF25 x1;iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4.Vacuum System and Vacuum Measurement:iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4.1 4L / s mechanical pump x 1iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4.2 F300 molecular pump x1iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4.3 Electromagnetic KF20 valve x1iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4.4 Vacuum gauge x 1iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4.5 Angle valve RF16, pipeline, joint, inflation valve D6, etc . x 1 way (to release vacuum nitrogen filling);iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4.6 KF25 electromagnetic pressure difference valve x 1iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

4.7 CF100 gate valve x 1iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

-

Armored heating sample assembly: 1 set.

The heating area is Φ50mmX100mm (H), the maximum temperature of substrate heating is RM -600℃iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

± 1℃, which is controlled by thermocouple closed-loop feedback.iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Equipped with a magnetic rotating shaft, the motor drive is less than 30 revolutions per minute.iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

-

Metal seal copper ring and fluorine rubber seal ring of related specifications x 1 complete set

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

-

Stainless steel fastening bolts, nuts, washers, etc x 1 complete set

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

8. Install the machine frame components x 1 setiRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Installation platform: The entire equipment is placed on a standard load-bearing electric box, and the box is spray-treated. Easy to disassemble, occupying a small area of 780mmX580mmx1200mm.iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

9. Power control system: 1 setiRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The power supply is placed on a standard electrical box and mounted on a system rack.iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

10. Homemade poweriRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

10.1. Control power supply x 1iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

10.2. Sample heating power supply x 1iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

11. Supporting PoweriRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

11.1Vacuum gauge power supply: 1 setiRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

11.2 DC 500W DC power supply: 1 setiRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

11.3 RF AC500W power supply: 1 setiRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

11.4 Flow display and flow controller: 1 setiRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

12. Spare parts: 1 setiRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

12.1 Oxygen-free copper gaskets (related specifications); SeveraliRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

12.2 Fluorine rubber seals: 1 setiRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

12.3 Baking belt: 1iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

12.4 Small stainless steel parts: severaliRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

12.5 Electrical fuses: 3 each.iRAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

-

Water Chiller: 1 set