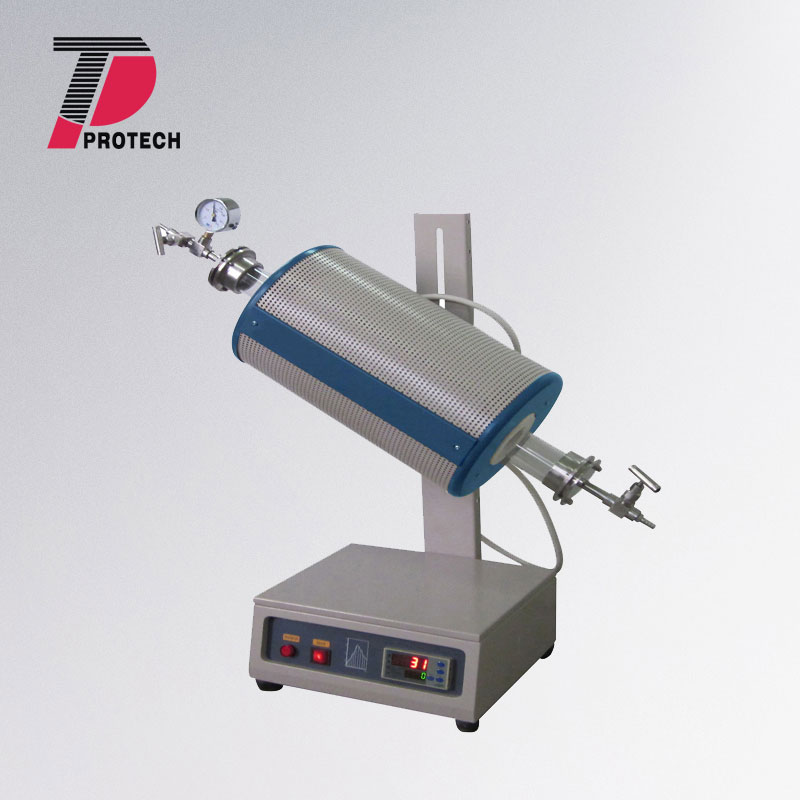

Description:

Multi station tubular furnace is designed for calcining inorganic compound with better uniformity. Such a unique motion pattern is also great for developing a conductive or protective coating on Li-Ion battery cathode/anode powder in R&D Laboratory, such as LiFePO3, LiMnNiO3, etc.

1.Features of Multi station tubular furnace:

(1). Operation Temperature: 1100℃ (1200℃ for short time).

(2). Maximum energy efficiency is achieved by surrounding the chamber with thermal-efficient alumina fiber ceramic insulation.

(3). Heavy duty double layer structure. Lower teperature in outside case.

(4). PID automatic control via current limiting phase angle fired the resistor, e.g. SCR(Silicon Controlled Rectifier).

(5). Power control with 30 segments programmable.

(6). Can be rotated in 360° according to your requirement.

We have a wide range of different optional function furnace to meet different heating requirement, also we accept customer design furnace R&D working, please email us your specific requirement, we will recommend most reasonable choice for you, thanks!

2.Descriptions of Multi station tubular furnace :

|

Chamber Size

|

Ø60x300mm (2.5"x12")

|

|

Working Temperature

|

1100℃ (continuous)

|

|

Maximum Temperature

|

1200℃ (for short time)

|

|

Temperature Control

|

30 steps programmable and PID automatic control

|

|

Heating Rate

|

0~10℃/min

|

|

Temperature Accuracy

|

+/-1℃

|

|

Heating Element

|

Resistance wire

|

|

Work station

|

Can be rotated in 360°

|

|

Working Voltage

|

AC 220V, Single Phase, 60/50 Hz (or according to your requirement)

|

|

Max. Power

|

2 KW

|

Multi station tubular furnace can be customized according to customers’requirements.