EXPLORE THE NEW TRENDS AND ADVANCED TECHNOLOGIES IN THE HEAT TREATMENT EQUIPMENT INDUSTRY

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

When selecting a crucible furnace, multiple factors need to be considered to ensure that the selected equipment can meet the needs of experiments or production. So what are the main aspects to pay attention to when choosing a crucible furnace?

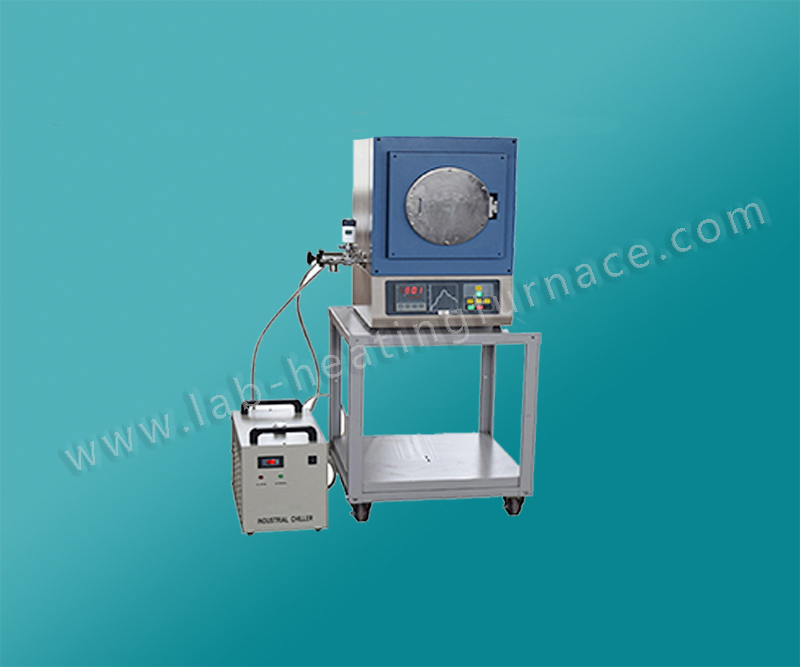

A commonly used upper door crucible furnace (click on the image to view product details)

Usage temperature and model:

Crucible furnaces are classified according to their operating temperatures, typically including the 1000 degree series, 1200 degree series, 1400 degree series, 1700 degree series, etc.

At the same temperature, crucible furnaces are also divided into different models based on their different volume sizes.

Select the appropriate model and temperature series based on actual needs and target temperature range.

Furnace material:

The furnace material of a conventional crucible furnace is silicon carbide.

The new type of crucible furnace may use ceramic fiber furnace material, which has better insulation effect and durability.

Select the appropriate furnace material according to the specific requirements of the experiment or production.

Heating element:

Crucible furnaces below 1200 degrees typically use alloy heating wires as heating elements.

The 1400 degree crucible furnace uses silicon carbon rods as heating elements.

The 1700 degree crucible furnace uses silicon molybdenum rods as heating elements.

Select the appropriate heating element based on the target temperature.

Structural type:

Split type crucible furnace: The temperature control system and furnace body are separate, suitable for scenarios that require flexible layout and large operating space.

Integrated crucible furnace: The control system and furnace body are integrated, making operation more convenient. It is suitable for scenarios with limited space or requirements for convenient operation.

Choose the appropriate structural type based on actual needs and usage scenarios.

Technical parameters:

Pay attention to technical parameters such as power, temperature control method, heating rate, and constant temperature accuracy of the crucible furnace.

For example, the power supply voltage of a certain model of crucible furnace is 3-phase 380V, the power is 50KW, the rated temperature is 900 ℃, and the heating element is heated by Kejia electric furnace high-temperature resistance wire.

Select a crucible furnace with matching technical parameters based on specific experimental or production requirements.

Other considerations:

Safety: Consider the safety devices of the crucible furnace, such as emergency stop switches, over temperature alarms, etc.

Durability: Consider the durability of the furnace and heating elements to ensure long-term stable operation of the equipment.

After sales service: Choose suppliers with good after-sales service to obtain timely technical support and repair services during use.

Side door crucible furnace (click on image to view product details)

So, when choosing a crucible furnace, it is necessary to comprehensively consider the temperature and model, furnace material, heating elements, structural type, technical parameters, and other considerations. By carefully comparing the performance and characteristics of different products, choose the crucible furnace that best suits your needs.Click to learn more Crucible Furnace! Or click on online customer service to learn more about product information!