EXPLORE THE NEW TRENDS AND ADVANCED TECHNOLOGIES IN THE HEAT TREATMENT EQUIPMENT INDUSTRY

Ask for a free consultation Ask for technical support

Tel

WhatsApp/WeChat

Contact Us

All products are customizable, leave message immediately, we will reply as soon as possible.

The vacuum furnace is a device that is discharged by some substances in a specific space and some substances can be discharged through the vacuum system to make the internal pressure in the stove cavity less than a standard atmospheric pressure, thereby achieving the space vacuum state in the furnace cavity. There are many types of vacuum furnaces, including vacuum welding furnaces, vacuum burns, vacuum heat treatment furnaces, vacuum industrial furnaces, vacuum heat pressure furnaces, vacuum retirement furnaces, etc., and are divided into vacuum resistance furnaces, molybdenum screen live furnaces, graphite, graphite Vacuum furnace, etc.

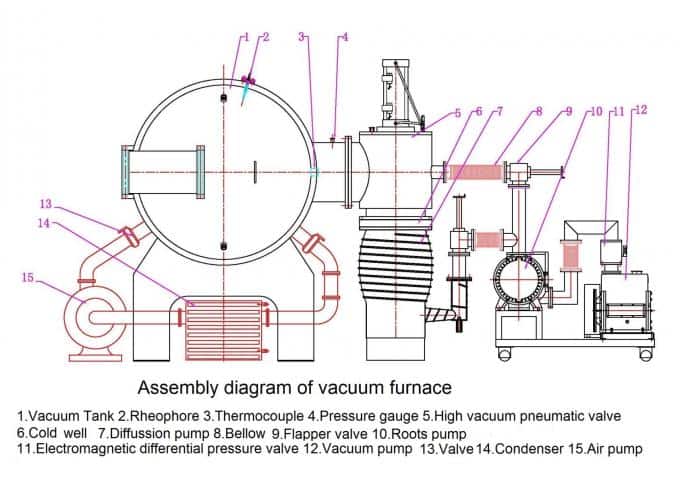

Common vacuum furnace structure diagram

What are the applications of vacuum furnaces?

① The field of metal materials: Vacuum furnaces are widely used in the field of metal materials, and are mainly used for metal thermal treatment and quenching processes. For example, vacuum retirement furnaces, vacuum retro -fire furnaces, etc. are used for thermal treatment of stainless steel, titanium alloy, bearing steel and other materials to improve their mechanical performance, organizational structure and chemical composition.

② Powder Metallurgical: In the powder metallurgical process, the vacuum furnace is used for sintering metal powder to prepare various metal parts and composite materials. The vacuum environment can reduce the surface oxidation of the material and improve the density and performance of the material.

③ Glass processing: In the glass industry, the vacuum furnace is used in the process of glass molding, coating, and heat treatment. The vacuum environment can prevent glass surface oxidation and bubble formation, and improve glass quality and optical properties.

④ Ceramic material: Since there is no oxygen in the vacuum furnace, it can effectively avoid adverse reactions such as oxidation and carbonization of ceramic materials. Therefore, vacuum furnaces are widely used for sintering, hardening, and melting of ceramic materials. In addition, the vacuum furnace can also be used to prepare some high -purity oxide ceramic materials, such as alumina.

⑤ Semiconductor manufacturing: Semiconductor materials are easy to oxidize at high temperatures, while there is no oxygen in the vacuum furnace, which can effectively avoid the oxidation damage of the material. Therefore, vacuum furnaces are widely used in the process of annealing, corrosion, and carving of semiconductor materials. In addition, in the process of semiconductor manufacturing, the vacuum furnace can also be used to prepare electron beam evaporation and chemical gas deposition.

⑥ Medical devices: In the manufacturing process of medical devices such as artificial joints, vacuum furnaces can be used for high temperature and heat treatment processes, so that artificial joints and other equipment have better corrosion resistance and mechanical properties.

⑦Alits: In the field of aerospace, vacuum furnaces also play an important role. In the manufacturing process of components such as aviation engines and rocket engines, vacuum furnaces can be used to perform technologies such as heat treatment, melting and material repair to improve the service life and performance of components. ⑧Electronic devices: In the process of electroplating and etching, the vacuum furnace can maintain a high vacuum state for a long time in order to ensure the stability and accuracy of the processing process.

⑨Heat Treatment Experiment: In scientific research and laboratory, vacuum furnaces are used for thermal treatment experiments and research of various materials. The vacuum environment can reduce oxidation reactions and impurities doping, and provide more pure experimental conditions.

Various vacuum furnaces (click the picture to view more vacuum furnaces)

Vacuum furnaces have important applications in metal processing, semiconductor manufacturing, glass industry, ceramic technology and scientific research fields, and provide key equipment and technical support for materials processing and research.

Please note that although the application range of real vacuum furnaces is widely used, different types of vacuum furnaces have different characteristics and applicable scenarios. Therefore, when selecting and applying a vacuum furnace, comprehensive considerations are required according to specific process needs, material characteristics, and equipment performance. At the same time, the operation and maintenance of the vacuum furnace also requires professionals to ensure the safety and stability of the equipment. Click to learn more about the vacuum furnace! Or click on online customer service to learn more about product information!