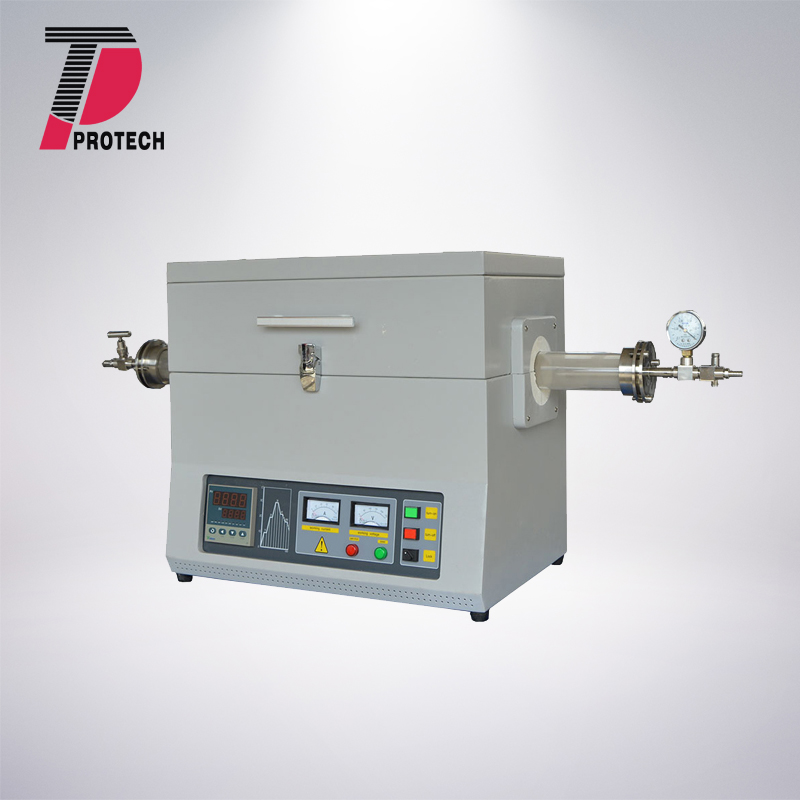

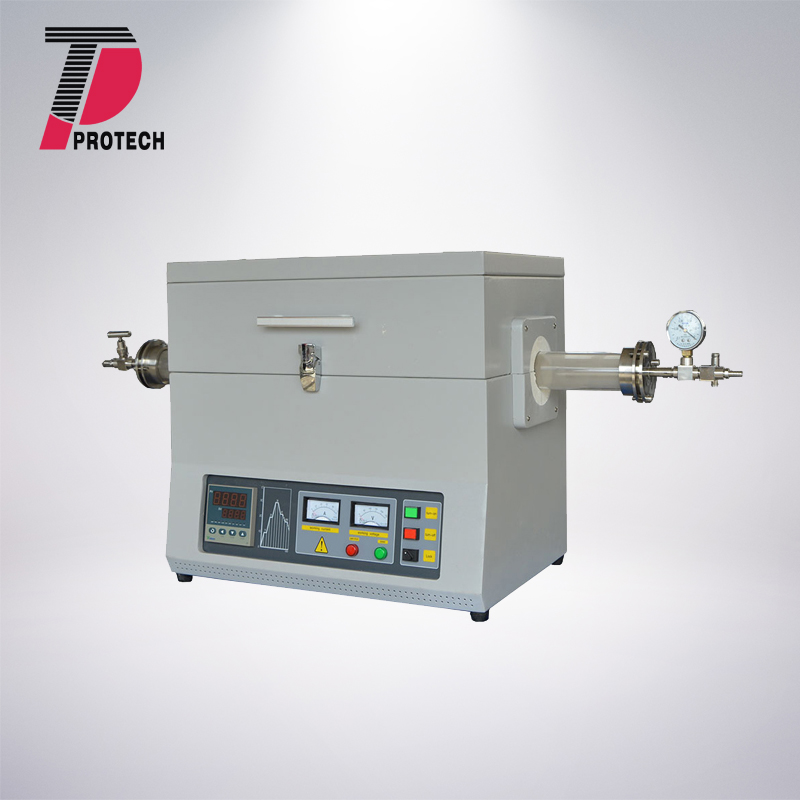

Vacuum tube furnaces are all cyclical. For laboratory, industrial and mining enterprises, scientific research units for elemental analysis and determination of general small steel parts quenching, annealing, tempering and electronic ceramics and other new materials for heating. Its characteristics are safe and reliable, energy saving, fast lifting temperature, low energy consumption and long service life. When using the vacuum tube furnace for the first time, in order to ensure its service life, you need to pay attention to the following details. Let's take a look!JZAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

JZAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

JZAMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Vacuum tube furnaces (Click on the image to learn more)

1. After the furnace is used for the first time or after a long time of use, it should be baked at 120 °C for 1 hour and baked at about 300 °C for 2 hours to avoid cracking of the furnace.

The furnace temperature should not exceed the rated temperature as much as possible to avoid damage to the heating element and the lining. It is forbidden to directly inject various liquids and dissolved metals into the furnace to keep the furnace clean.

2, the occurrence of devitrification defects is a normal phenomenon

If the furnace is made of quartz tube, when the temperature is higher than 1000 °C, the high temperature part of the quartz tube will appear opaque. This is called devitrification (also called devitrification), which is an inherent defect of the fused quartz tube, which is a normal phenomenon.

3. When the furnace is used, the heating rate in the low temperature section is not too fast.

When the furnace is used, since the furnace is cold, it needs a large amount of heat absorption, so the heating rate in the low temperature section is not easy to be too fast, and the difference in the heating rate of each temperature section is not too large. The physicochemical properties of the sintered material should be fully considered when setting the heating rate. In order to avoid the phenomenon of spraying, pollute the furnace tube.

4. Regularly check the temperature control system

Regularly check the contact of the electrical connection part of the temperature control system is good, pay special attention to whether the connection of each connection point of the heating element is tight.

5, timely replacement of temperature resistant silicone ring between stainless steel flanges

After the furnace has been used for a period of time, if the vacuum is reduced, replace the temperature resistant silicone ring between the stainless steel flanges or reinstall the stainless steel flange or replace the vacuum system to improve the overall vacuum of the system.